Polypropylene is a versatile plastic that is used in a wide range of applications, including packaging, textiles, automotive components, and more. The new extrusion process developed by JWELL Machinery promises to make the production of polypropylene products more efficient, cost-effective, and environmentally friendly.

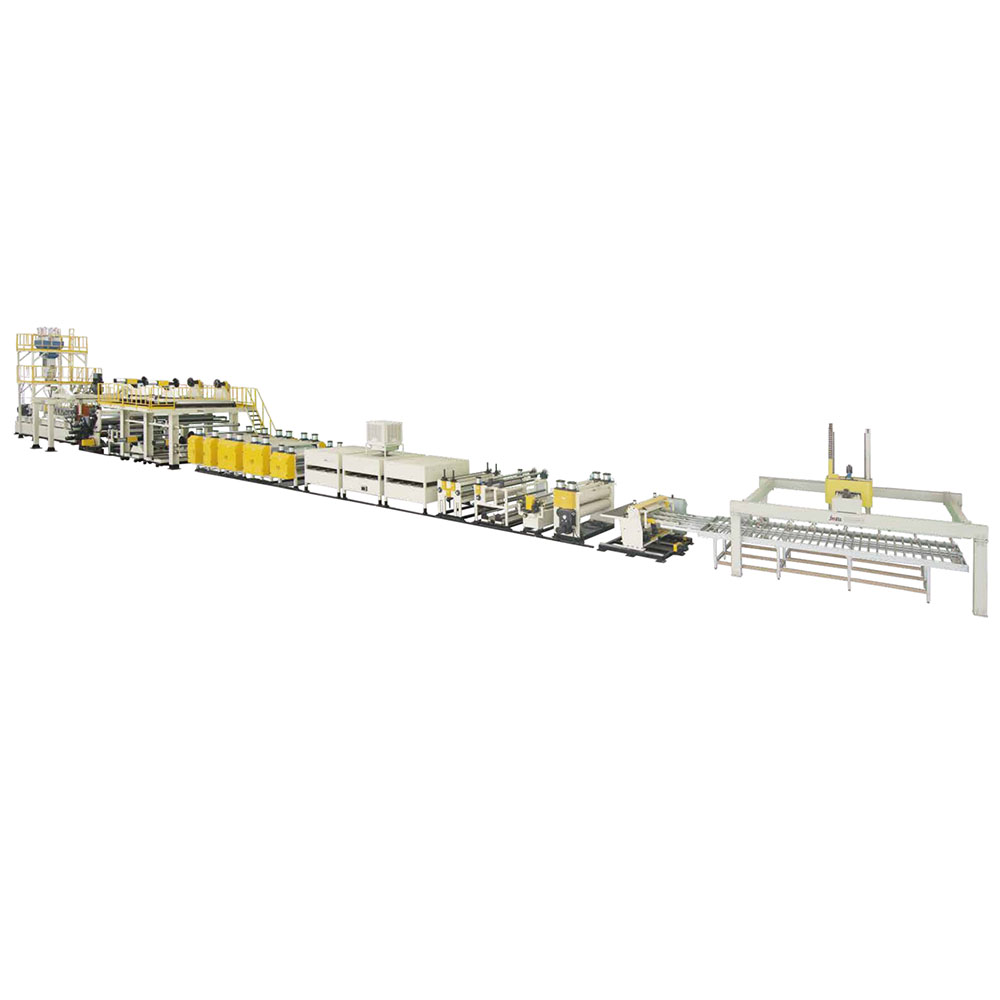

The extrusion process is a manufacturing technique used to create objects of a fixed cross-sectional profile. It involves pushing material through a die of the desired shape, which then solidifies into the final product. The new process developed by JWELL Machinery incorporates cutting-edge technology and innovative design to improve the efficiency and quality of polypropylene extrusion.

One of the key benefits of this new process is its ability to produce polypropylene products with enhanced strength and durability. This is achieved through precise control of the extrusion process, resulting in products that are better suited for demanding applications such as automotive components and industrial packaging.

In addition to improved performance, the new extrusion process also offers significant cost savings. By optimizing the production process, JWELL Machinery is able to reduce material waste and energy consumption, resulting in lower production costs. This not only benefits manufacturers who use polypropylene in their products, but also contributes to a more sustainable and environmentally friendly manufacturing process.

The development of this new extrusion process is a testament to JWELL Machinery's commitment to innovation and excellence in the field of plastic extrusion. With over two decades of experience in the industry, the company has established itself as a leader in the development of cutting-edge manufacturing technologies.

The company's seven manufacturing plants in China mainland and one in Thailand are equipped with state-of-the-art facilities and a team of skilled engineers and technicians. This enables JWELL Machinery to continuously push the boundaries of what is possible in plastic extrusion, and to develop new and improved processes that benefit their customers and the industry as a whole.

JWELL Machinery's new polypropylene extrusion process is set to have a significant impact on the industry, and is expected to be widely adopted by manufacturers looking to improve the quality and efficiency of their polypropylene products. As the demand for high-performance and sustainable materials continues to grow, this new process will play a crucial role in meeting the needs of the market.

In conclusion, the development of a new extrusion process for polypropylene by JWELL Machinery represents a major advancement in the field of plastic extrusion. With its improved performance, cost savings, and environmental benefits, this new process is set to revolutionize the production of polypropylene products and make a significant impact on the industry. JWELL Machinery's commitment to innovation and excellence has once again positioned them as a leader in the development of cutting-edge manufacturing technologies.