Established in 1997, JWELL Machinery has continuously raised the bar in the plastic extrusion industry. With seven manufacturing plants in China mainland and one in Thailand, the company has solidified its reputation as a top-tier supplier of plastic extrusion machines. Their commitment to quality, efficiency, and customer satisfaction has earned them a strong presence in the market.

As the demand for PE sheet extrusion continues to grow, JWELL Machinery has risen to the occasion with their advanced equipment and expertise in the field. PE sheet extrusion, also known as polyethylene sheet extrusion, is a process of creating continuous sheets of plastic using a variety of materials, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE). These sheets are widely used in various industries, such as packaging, construction, automotive, and agriculture.

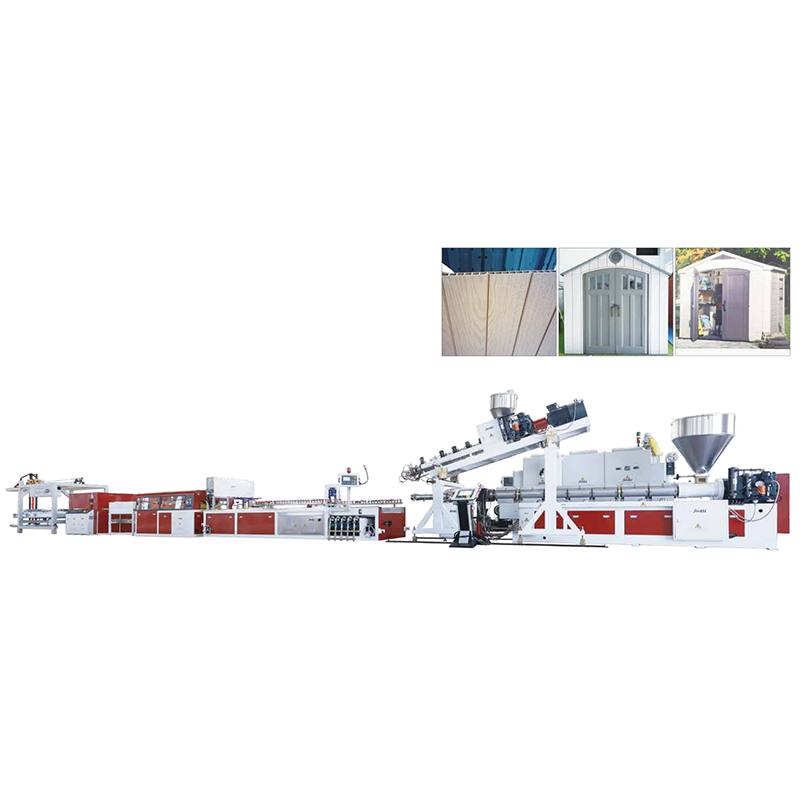

With their state-of-the-art extrusion technology, JWELL Machinery has been able to meet the diverse needs of their customers in the PE sheet extrusion market. Their machinery is capable of producing PE sheets of different thicknesses, widths, and specifications, allowing for a wide range of applications. Whether it's for food packaging, geomembranes, or industrial liners, JWELL Machinery has the capability to deliver high-quality PE sheets that meet industry standards and exceed customer expectations.

One of the key factors that sets JWELL Machinery apart in the PE sheet extrusion market is their dedication to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and remain at the forefront of technological advancements in the plastic extrusion industry. This commitment to innovation has enabled JWELL Machinery to develop cutting-edge machinery that delivers superior performance, energy efficiency, and cost-effectiveness.

Furthermore, JWELL Machinery places a strong emphasis on customer satisfaction, offering comprehensive support and services to ensure the success of their clients. From initial consultation to after-sales support, the company works closely with their customers to understand their specific requirements and provide tailored solutions that meet their needs. Whether it's customizing machinery, providing technical training, or offering maintenance services, JWELL Machinery is dedicated to building long-lasting relationships with their clients and helping them achieve their production goals.

In addition to their technological prowess and customer-centric approach, JWELL Machinery also places a strong emphasis on sustainability and environmental responsibility. With the increasing global focus on reducing plastic waste and promoting eco-friendly practices, the company has integrated sustainable solutions into their manufacturing processes. Their PE sheet extrusion machinery is designed to optimize material usage, minimize energy consumption, and reduce carbon footprint, aligning with the growing demand for green technologies in the industry.

Looking ahead, JWELL Machinery is poised to continue its leadership in the PE sheet extrusion market, capitalizing on the increasing demand for high-quality plastic sheets across various industries. With their unwavering commitment to excellence, innovation, and sustainability, the company is well-positioned to meet the evolving needs of their customers and drive the advancement of plastic extrusion technology.

As the global market for PE sheet extrusion continues to expand, JWELL Machinery remains a trusted partner for businesses seeking reliable and efficient solutions for their plastic extrusion needs. With their unparalleled expertise, state-of-the-art machinery, and customer-oriented approach, the company is set to shape the future of PE sheet extrusion and make a significant impact in the plastic manufacturing industry.