The manufacturing industry is constantly evolving, and the advent of 3D printing has revolutionized how things are designed and produced. Additive manufacturing has provided designers and engineers with a powerful tool to create complex and intricate parts in a cost-effective and sustainable manner. Material extrusion-based 3D printing is a popular method of creating 3D-printed objects, particularly for thermoplastic materials. This blog discusses how embedding mica platelets into polyetherketoneketone can improve its properties in the extrusion process for thermoplastic materials.

What is Material Extrusion-Based 3D Printing?

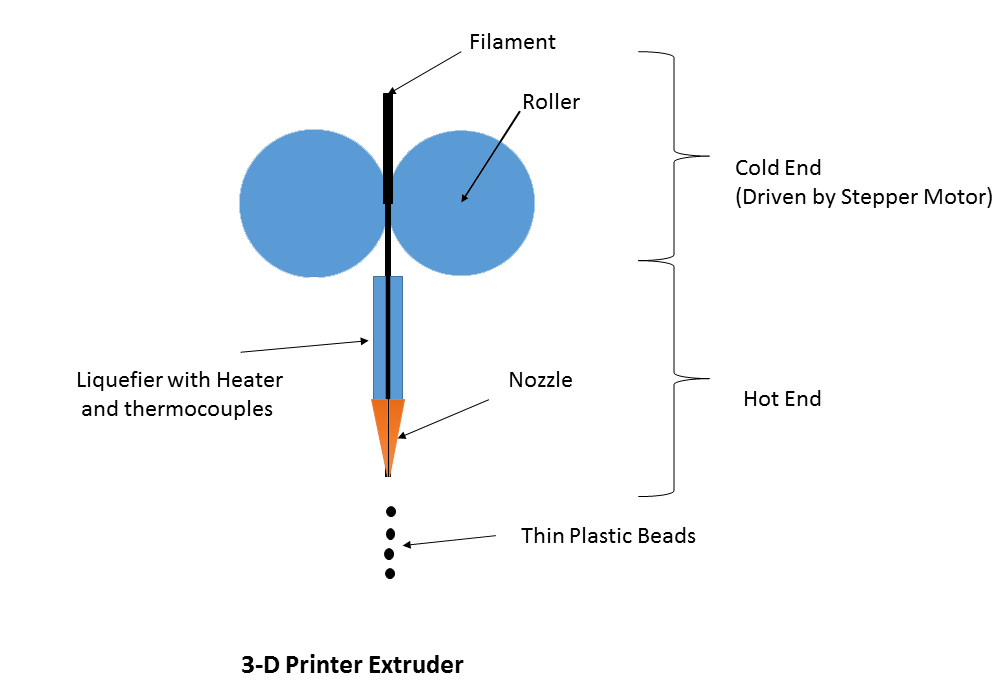

Material extrusion-based 3D printing is a 3D printing technology that uses a nozzle to deposit melted thermoplastic material layer by layer to form a 3D object. The process starts by feeding raw thermoplastic material into a heated extruder, where it is melted and pushed through a nozzle. The nozzle moves back and forth, and the melted material is deposited layer by layer to create the final 3D object. Material extrusion-based 3D printing is ideal for creating parts with excellent dimensional accuracy, a high degree of complexity, and structural integrity.

Benefits of Mica-Involved Thermoplastic in Material Extrusion-Based 3D Printing

Mica platelets are thin, transparent, and resilient mineral sheets that are commonly used in the production of paint, coatings, and plastics. In a recent paper published in Additive Manufacturing, researchers demonstrated how embedding mica platelets into polyetherketoneketone can improve the properties of the material in the extrusion process for thermoplastic materials.

1. Enhanced Mechanical Properties

Polyetherketoneketone is a popular thermoplastic material used in a broad range of industries, including the automotive industry, because of its high strength, stiffness, and resistance to high temperatures. However, it can be brittle and prone to cracking when exposed to high stress or pressure. By embedding mica platelets in polyetherketoneketone, the researchers were able to significantly improve its mechanical properties. The introduction of mica platelets increased the material's stiffness, strength, and toughness while reducing its brittleness.

2. Improved Thermal Conductivity

Polyetherketoneketone is known for its excellent resistance to high temperatures, making it suitable for use in high-temperature applications. However, it can still suffer from thermal degradation when exposed to prolonged high temperatures. By adding mica platelets, which have high thermal conductivity, to polyetherketoneketone, the researchers were able to improve its thermal properties. The addition of mica platelets increased the material's ability to dissipate heat, reducing the risk of thermal degradation.

3. Increased Dimensional Stability

Polyetherketoneketone can undergo significant dimensional changes during the manufacturing process due to thermal expansion and contraction. This can result in parts with inaccurate dimensions, leading to fit and assembly issues. By embedding mica platelets in polyetherketoneketone, the researchers were able to improve its dimensional stability. The addition of mica platelets helped to reduce the material's thermal expansion and contraction, resulting in parts that maintain their shape and size.

Conclusion

In conclusion, embedding mica platelets in polyetherketoneketone can improve its properties, making it ideal for use in material extrusion-based 3D printing. The addition of mica platelets can enhance the mechanical properties, improve thermal conductivity, and increase dimensional stability of the material. As a result, designers and engineers can create complex and functional parts with more accuracy and structural integrity. The incorporation of mica platelets is a promising avenue for further improving the properties of thermoplastic materials for use in 3D printing.